CONTINUOUS DYEING -PAD DRY THERMOSOL

Pad Dry Thermosol Fabric Dyeing Lines:

The Thermosol Dyeing process is a continuous dyeing process that is based on a mechanical adsorption of the dye on the fiber, where insoluble dyes and pigments are deposited on the fiber.

It can be divided into 5 well-defined steps:

1. Color impregnation on dyeing padder

During this process, the fabric is immersed in the color bath and is subsequently squeezed into a foulard at a known pressure, which allows knowing the amount of dye that the textile fabric will have throughout the process and also allows the absorption to be adjusted. of the fabric.

2. Pre-drying

Once the fabric is impregnated, a pre-drying occurs in which the fabric reaches a temperature of between 80-90 °C. The main objective is to increase the diffusion of the dye over the fabric.

3. Heat setting

Thermosetting is a heat treatment in which the fiber is subjected to a temperature between 160 and 210 °C for a certain time. This step of the process is where the dye is fixed to the fiber.

4. Washing

Once the dye is already fixed in the fiber, the excess dye and other dyeing auxiliaries that have not been used and that remain on the already heat-set fabric must be removed.

To do this, a washing train with reducing baths is used that helps eliminate excess dye, as well as guarantee good rub fastness of the finished product.

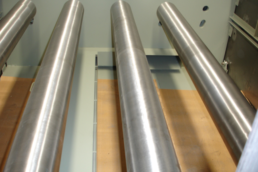

5. Drying

The final part of the process consists of drying the fabric on drying cylinders heated by steam.