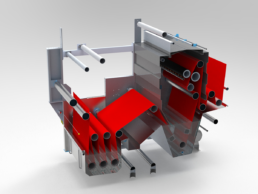

Washing: ICOWASH – Continuous De-Oiling unit for textile fabrics

With an efficiency much higher than that of a conventional washing box, the ICOWASH unit allows significant savings in impregnation products or washing products. Inside the ICOMATEX ICOWASH box we are forcing the washing process thanks to the suction groups under water, passing the bath through the fabric, obtaining more efficiency in the wash and accelerating production, reducing costs in chemical products and water consumption. The size of the ICOWASH unit is very compact and can be installed in existing lines.

Continuous De-Oiling unit for textil fabrics.

At ICOMATEX we can offer you our ICOWASH washing unit before the stenter. With an efficiency much higher than a complete tank. Our ICOWASH washing box allows significant savings on chemicals and delivers a much dryer fabric due to the vacuum slot system installed at the exit of the unit. .

The first step is a spray prewasher forcing the pass of the water from one side to the other, by means of vacuum unit. This process also reduces dramatically the humidity of the fabric to have the best conditions for higher pickup when is introduced into the impregnation bath where two submerged suction units force the pass of the chemicals throught the fabric, both in the same way or opposite, depending on the fabric needs.

Washing in front of the stenter can offer you a series of benefits that will surely be of interest to you:

BENEFITS

- OIL REMOVING BEFORE DYEING OR PRINTING

- BETTER COLOUR AFFINITY

- BETTER TOUCH

- LESS DYEING MARKS DUE TO OILS

- LESS SMOKE ON EXHAUST OF STENTER

- ABLE TO GET PFD AND PFP FABRICS