INSPECTION AND WINDING MACHINE

INSPECTION AND WINDING MACHINE

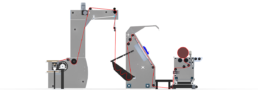

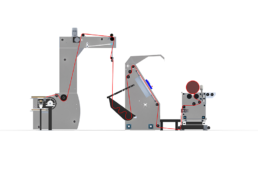

NON STOP UNIT / MODEL IC-21

- Reclining Nonstop ‘J’ box with fabric stop by photo-electric cell to work in line with previous machine.

- Motorized wideners working in all the width of the fabric, motor driven.

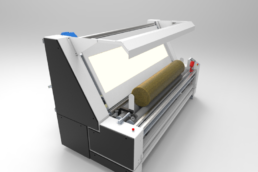

- Two cylinders speed regulators and tractor at the entry and exit of the table of inspection.

- Inspection inclined table and covered with Formica.

- Free pass cylinder, for fabric inlet to the cart centering.

- Photo-electric cells intercalated between the free pass cylinder and the widening cylinder, adjustable for different working widths, with limiters (cardboard tube stops), located on the winder.

- Motorized widening, erected on the centering cart and before the widening cylinders. Motor.

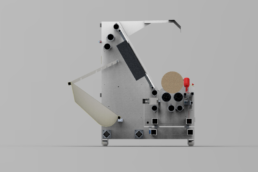

- Two motorized winding cylinders, with independent overfeeding each; diameter of the cylinders 170 mm.

- Automatic centering cart by motor and gearbox , with screw and nut scroll left or right, depending on the photoelectric cell signal.

- Motor and general motor through reducer , with electrical panel and external controls for all maneuvers.

- Lengthwise cutter piece by piece.

- Benches with doors inside which housed all drive elements and electrical panel.

Empty tab. Edit page to add content here.